| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Material | Stainless Steel |

| Class | Class 1 |

| Click to view more | |

Product Details

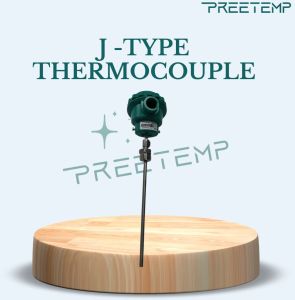

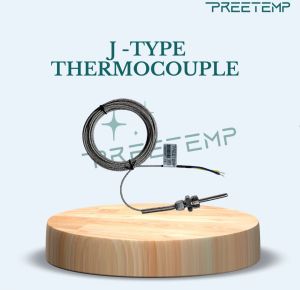

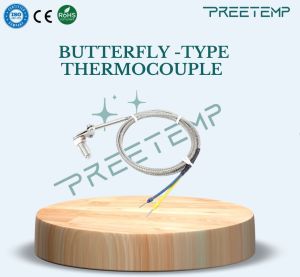

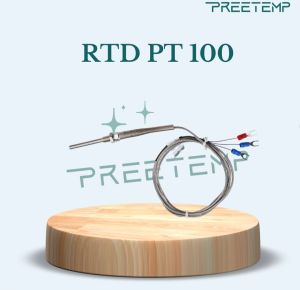

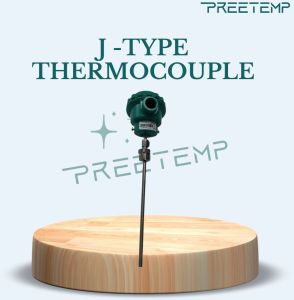

Thermocouple is a temperature-sensing device commonly used in food machinery to monitor and control temperatures during cooking, processing, or storage. It consists of two different metal wires joined at one end, creating a junction. When this junction experiences a change in temperature, it generates a voltage that can be measured and converted into a temperature reading.

Key Features of Thermocouples in Food Machinery:

-

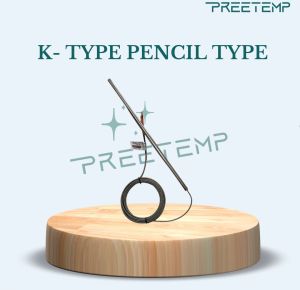

Material Types: Common thermocouple types used in food applications include Type K (Chromel-Alumel) and Type T (Copper-Constantan), chosen for their appropriate temperature ranges and durability.

-

Temperature Range: They can measure a wide range of temperatures, typically from -200°C to 1260°C (-328°F to 2300°F), making them suitable for various cooking processes.

-

Fast Response Time: Thermocouples provide quick temperature readings, which is crucial for processes requiring precise temperature control.

-

Robustness: Designed to withstand harsh environments, thermocouples are often encased in protective sheaths made of stainless steel or other materials resistant to corrosion and damage.

-

Ease of Integration: They can be easily integrated into existing food processing equipment and connected to digital displays or control systems for real-time monitoring.

-

Calibration: Regular calibration is essential to ensure accuracy, especially in critical applications where temperature control affects food safety and quality.

Applications in Food Machinery:

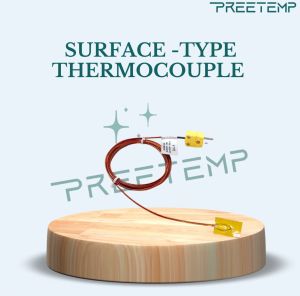

- Cooking Equipment: Monitoring internal temperatures in ovens, fryers, and grills.

- Refrigeration Systems: Ensuring proper storage temperatures in freezers and refrigerators.

- Pasteurization: Verifying that food products reach the necessary temperatures to eliminate pathogens.

- Quality Control: Assuring consistent temperature profiles during processing to maintain product integrity.

Overall, thermocouples are vital in ensuring food safety, quality, and compliance with industry standards.