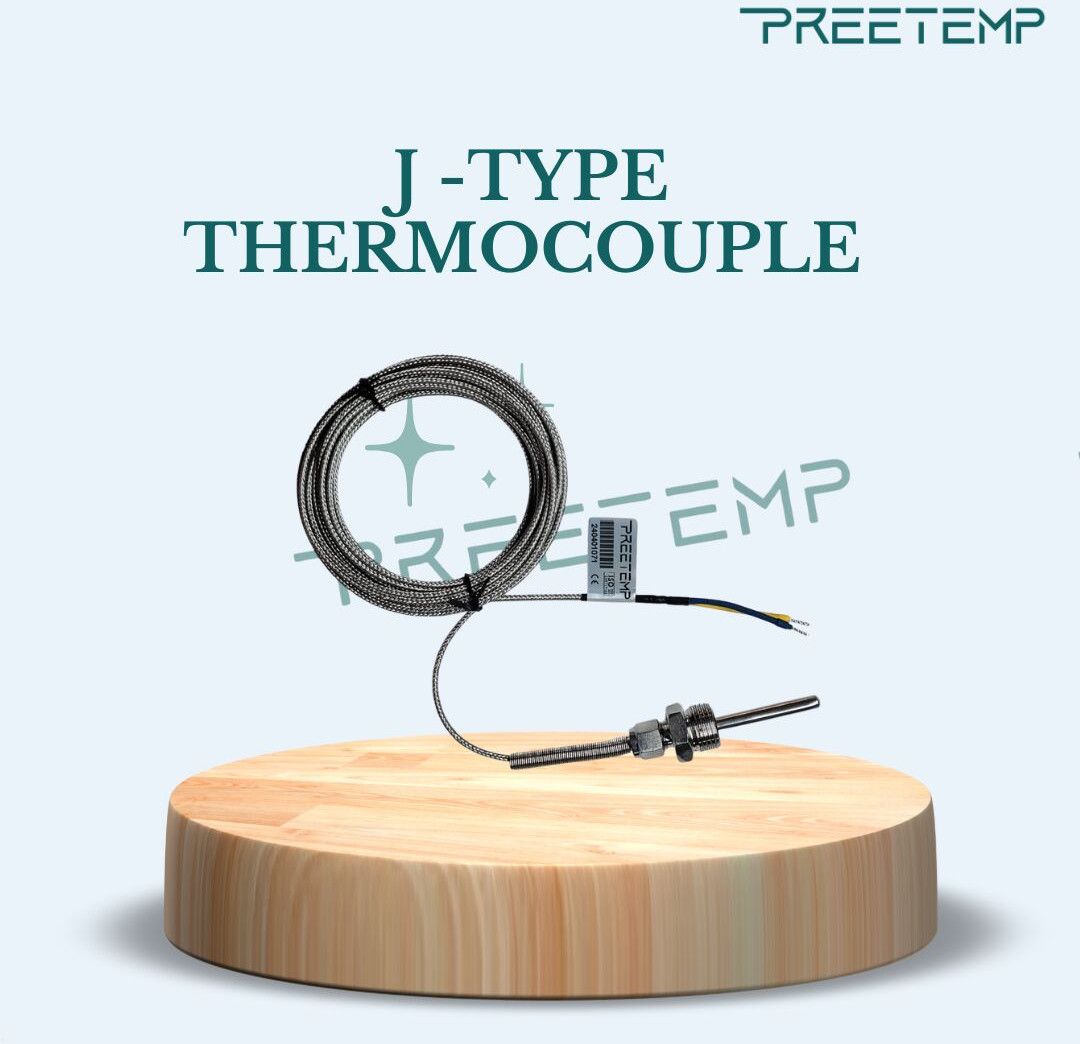

| Business Type | Manufacturer, Exporter, Supplier |

| Temperature Range | 0 To 750 Deg C |

| Country of Origin | India |

| Accuracy | +/-1.5 deg C or +/-0.4%) |

| Click to view more | |

Product Details

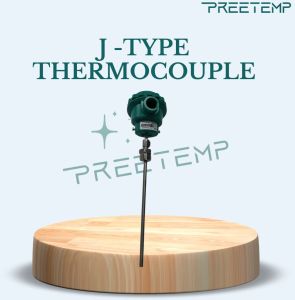

J-type thermocouple is a widely used temperature sensor that provides accurate temperature measurements in various industrial and laboratory applications. It consists of two dissimilar metal wires that generate a voltage proportional to the temperature difference between the junction and a reference point. Here’s a detailed description of its components, design, functionality, applications, and advantages:

Components and Design

-

Thermocouple Wires:

- Materials: The J-type thermocouple consists of two wires made from iron (Fe) and constantan (a copper-nickel alloy). The combination of these metals produces a measurable voltage when subjected to a temperature gradient.

- Junction: The point where the two wires are joined forms the thermocouple junction, where temperature sensing occurs.

-

Insulation:

- The individual wires are often insulated with materials that can withstand high temperatures and provide electrical isolation. Common insulation materials include ceramic, fiberglass, or high-temperature plastics.

-

Protective Sheath:

- The thermocouple is typically enclosed in a protective sheath made of stainless steel or other resistant materials. This sheath protects the sensor from mechanical damage, chemicals, and extreme temperatures.

- The sheath can be available in various diameters and lengths, allowing customization based on the application.

-

Connector:

- At the end of the thermocouple, a connector (such as a mini or standard thermocouple connector) allows for easy attachment to measurement devices or control systems.

Functionality

-

Temperature Measurement:

- J-type thermocouples can measure temperatures ranging from approximately -40°C to 750°C (-40°F to 1382°F), although they can handle higher temperatures in specific configurations.

-

Electrical Output:

- The voltage generated at the thermocouple junction varies with temperature. This voltage is then measured and converted into a temperature reading using suitable instrumentation.

-

Response Time:

- The response time of a J-type thermocouple can be fast, depending on the design. Grounded junction configurations typically provide quicker response times compared to ungrounded types.

Applications

-

Industrial Processes:

- Widely used in chemical processing, oil and gas, and manufacturing for monitoring temperatures in reactors, furnaces, and heat exchangers.

-

Power Generation:

- Employed in power plants for temperature monitoring in turbines, boilers, and other critical equipment.

-

Food Processing:

- Used for ensuring proper cooking and storage temperatures in food manufacturing, helping to maintain safety and quality standards.

-

Research Laboratories:

- Commonly found in laboratory environments where precise temperature measurements are critical for experiments and testing.

Advantages

-

Good Accuracy:

- They provide reliable and accurate temperature measurements, essential for process control and monitoring.

-

Wide Availability:

- J-type thermocouples are widely available and can be sourced from various manufacturers, ensuring compatibility with many systems.

-

Fast Response Time:

- Suitable for applications requiring quick temperature measurements, especially when configured with grounded junctions.